With the release of its new patent-pending Caliber Matched Gas System (CAMGAS) barrels, PROOF Research has eliminated the issues traditionally associated with building .22 Nosler, 6.5mm and .260 rifles on 308AR/AR-10 platforms. Until now, AR-variant shooters looking for ballistic advantages from either of these calibers were faced with excessive bore pressures that necessitated makeshift solutions such as clipping buffer springs, adjusting buffer weights, and/or relying on adjustable gas blocks, to keep their rifles functioning properly.

PROOF’s R&D team has solved the overpressure issue with gas systems tuned specifically to the cartridge/barrel-length combination. “By moving the gas port, the pressure in the bore is given time to reduce to that comparable of a [.223 Winchester] with a rifle-length gas system, which is what the system was designed around,” said Greg Hamilton, PROOF’s research-and-development weapons specialist who’s also a 3-Gun and PRS competitive shooter. “The recoil impulse is noticeably smoother, which helps keep you on target while taking advantage of a more efficient projectile. Case extraction is also easier, with less case-head smearing, so the brass is in much better condition for reloading.”

PROOF Research currently offers Caliber Matched Gas System barrels chambered for .22 Nosler, 6.5mm Creedmoor and .260 Remington.

THE ONLY CARBON FIBER-WRAPPED BARREL APPROVED FOR USE BY THE U.S. MILITARY.

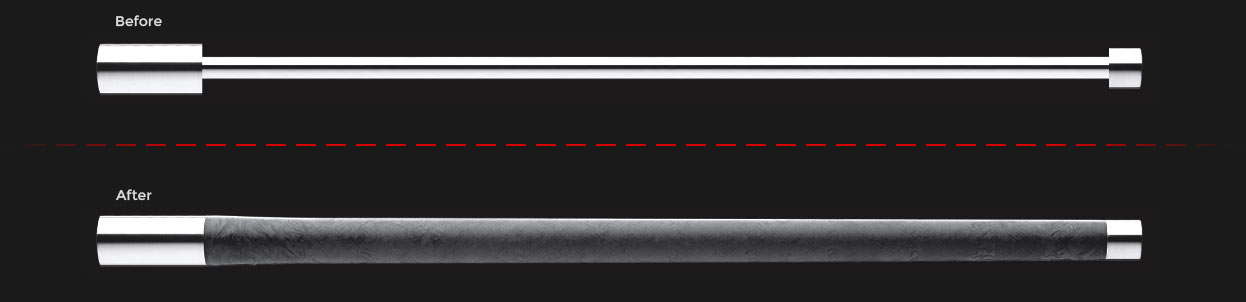

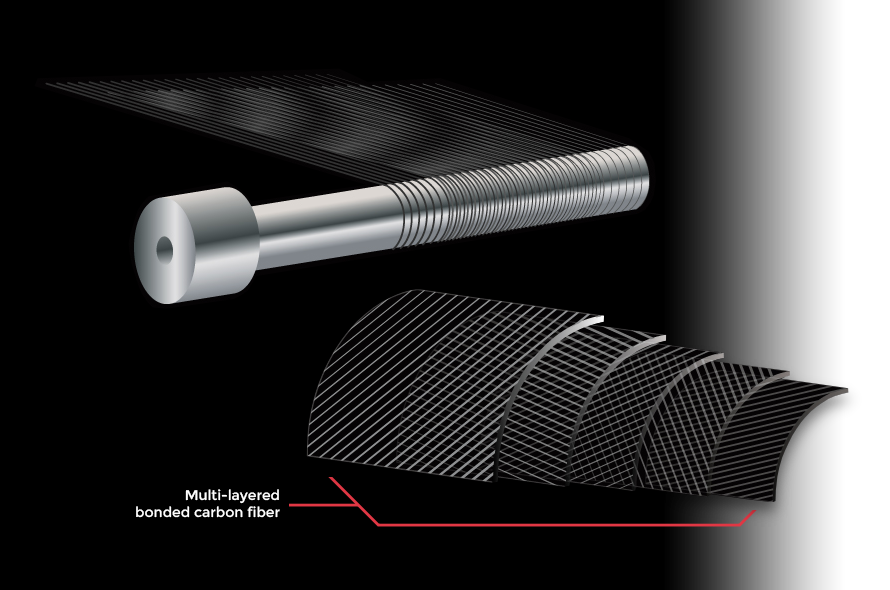

This patented manufacturing process begins with full-profile, match-grade 416R stainless steel barrel blanks that are made in our firearms division. These blanks are then turned down to a significantly reduced profile greatly reducing weight. This reduced contour barrel is then filament-wrapped with high-strength, aerospace-grade carbon fibers impregnated with a high-thermal conductivity matrix resin developed by our aerospace materials division.

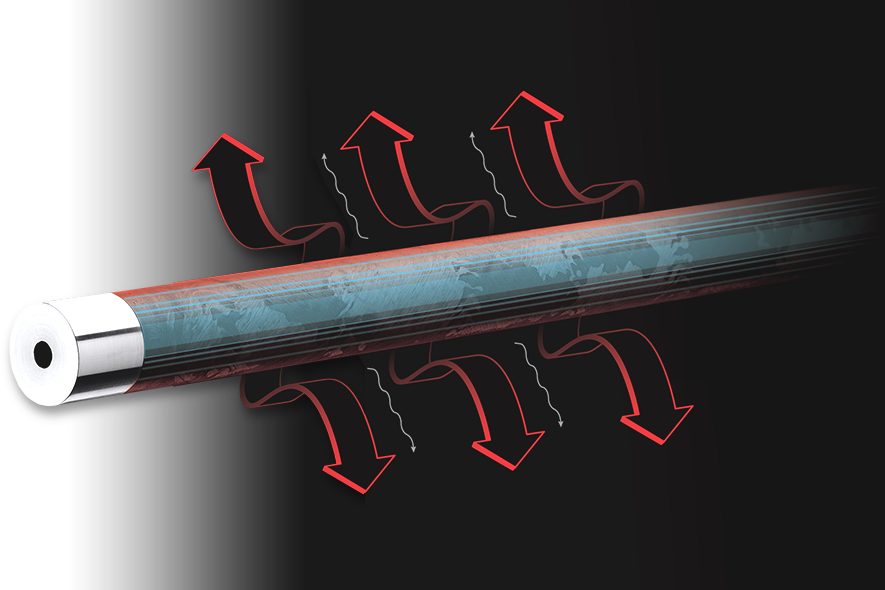

The aerospace-grade carbon fiber used is 10 times stronger than stainless steel and has a specific stiffness nearly 6 times greater than steel. But strength and stiffness are only part of the equation. Heat conductivity and thermal expansion are also of paramount importance when developing a match-grade, carbon fiber barrel. Our helical wrapping pattern favors the longitudinal thermal diffusivity of the carbon fibers (along the length of the barrel) allowing them to dissipate the heat emanating from the steel liner rather than insulate it. This is achieved through phonon transport in the direction of the continuous fibers and greatly reduces the mirage effect intrinsic in heavy steel barrels.

However, because our unique bonding agent contains a high-thermal pitch fiber—similar to those proven in Formula One and aerospace applications—our barrels also conduct heat very effectively through the wall (thickness) of the barrel, greatly increasing thermal conductivity and resulting in barrels that stay cooler and maintain accuracy over longer sessions of fire.

After wrapping, barrels are cured and consolidated then ground to their final contour. The end result is an aerospace-grade, high-fiber volume fraction composite barrel with less than 1% porosity suitable for the most extreme environments and capable of shot-after-shot accuracy that will impress the most veteran hunter or precision marksmen.

PROOF Research’s match-grade carbon fiber barrels are stronger, lighter, as accurate as the finest precision steel barrels and will maintain their performance in the harshest conditions. PROOF didn’t invent carbon fiber-wrapped barrels. They just perfected them.

- Up to 64% lighter than traditional steel barrels

- Match-grade accuracy

- Improved heat dissipation for cooler and longer lasting barrels

- No point-of-impact shift during high-volume fire

- Reduced harmonic barrel vibration

- Unprecedented durability

Barrels are available for both bolt-action and AR-style rifles, in a variety of calibers, lengths and twists. This is the AR-15 page.

Your AR barrel is pre-chambered in the cartridge of your choice and ready for installation by your gunsmith. All AR-15 barrels are headspaced for the JP EnhancedBolt™ Get yours here.

The .223 Wylde is a proprietary rifle cartridge chamber with the external dimensions and lead angle as found in the military 5.56×45mm NATO cartridge and the 0.224 inch freebore diameter as found in the civilian SAAMI .223 Remington cartridge. Rifles with a .223 Wylde chamber will typically accept both .223 Remington and 5.56×45mm NATO ammunition. Note that while the .223 Remington and 5.56×45mm NATO chambers have slightly different dimension, the cartridges themselves are identical in dimension. The chamber dimension differences are often confused with the cartridge dimensions and so it is often erroneously thought that the cartridges have different dimensions. The cartridges are loaded to different pressure levels (with the 5.56 being greater), however. (The NATO dimensions offset the higher pressure with a longer throat - often confusing some to think the cartridge itself is longer). This chamber allows the use of both pressure levels safely while also increasing accuracy potential across the range of potential pressures.

The .223 Wylde hybrid chamber was designed by Bill Wylde to exploit the accuracy advantages of the .223 Remington chambering without pressure problems or compromising the functional reliability of semi-auto weapons like the AR-15 family when using 5.56×45mm NATO military ammunition. Coincidentally, it shoots the relatively long and heavy 80-grain bullets commonly used in the Sport Rifle Competition very well and is one of the preferred chambers for that use.

- Brand:

- Proof Research